PROUD OF OUR SERVICES!

In addition to facilities that produce and recycle fuel, Orano offers a wide range of services to customers all over the world, ranging from transport, engineering and production support to dismantling.

NUCLEAR PACKAGES AND SERVICES

Boasting over 60 years’ experience, Orano NPS is the global expert in the design, approval and manufacturing of casks and the transportation of nuclear materials for customers worldwide. Orano NPS is also a leading player in the dry storage of used fuel, offering a comprehensive range of nuclear logistics services, including solutions tailored to each market.

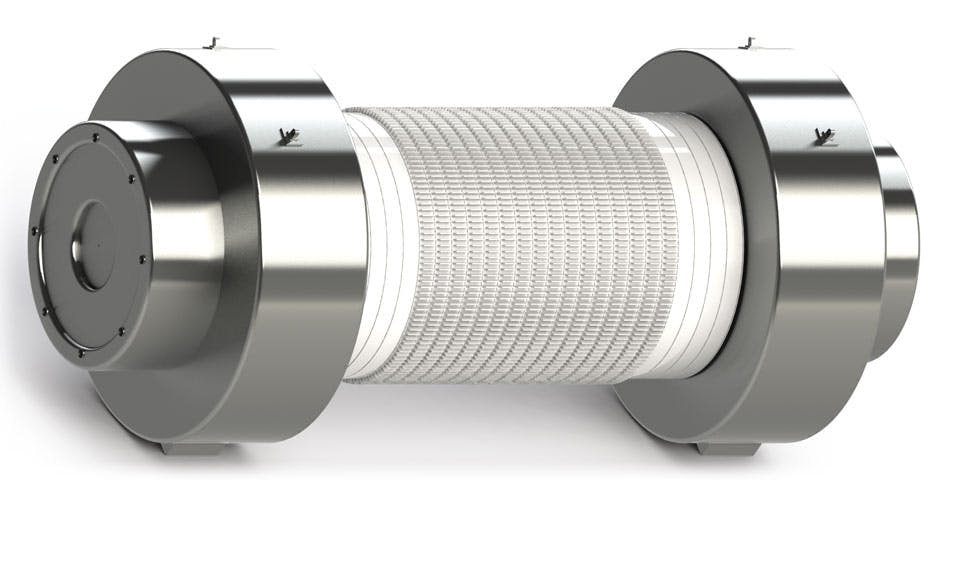

TN Eagle: innovative packaging concept for the shipping and dry storage of used nuclear fuel

Thanks to a tenfold reduction in the number of components, the TN Eagle’s modular and simplified design enables final assembly without welding, resulting in greater robustness and a manufacturing time of 18 months compared to an average 36 months for the previous generation of packaging. The TN Eagle has obtained shipping approval from the French nuclear safety authority (ASN) in accordance with the latest IAEA requirements. It will be manufactured using an innovative process at the highly automated TN Eagle Factory, a 4.0 facility located in the port of Cherbourg.

Transport services that comply with the most stringent French and international safety requirements

Whether upstream or downstream of the nuclear fuel cycle, we have unparalleled expertise in nuclear material transport solutions, as well as a large fleet of vehicles comprising 150 trucks, including 70 heavy load transporters, and 65 special wagons, plus long-term partnerships with shipping companies and airlines. We carry out over 6,000 shipments per year for utility customers, research reactors and laboratories. As a further innovation, we rent out our new DN30 packaging model for transporting enriched uranium.