REINVENTINGour business models

Backed by its unrivaled expertise in the recycling and recovery of strategic materials in the fuel cycle, Orano is exploring new areas of activity to serve the energy transition and industrial sovereignty.

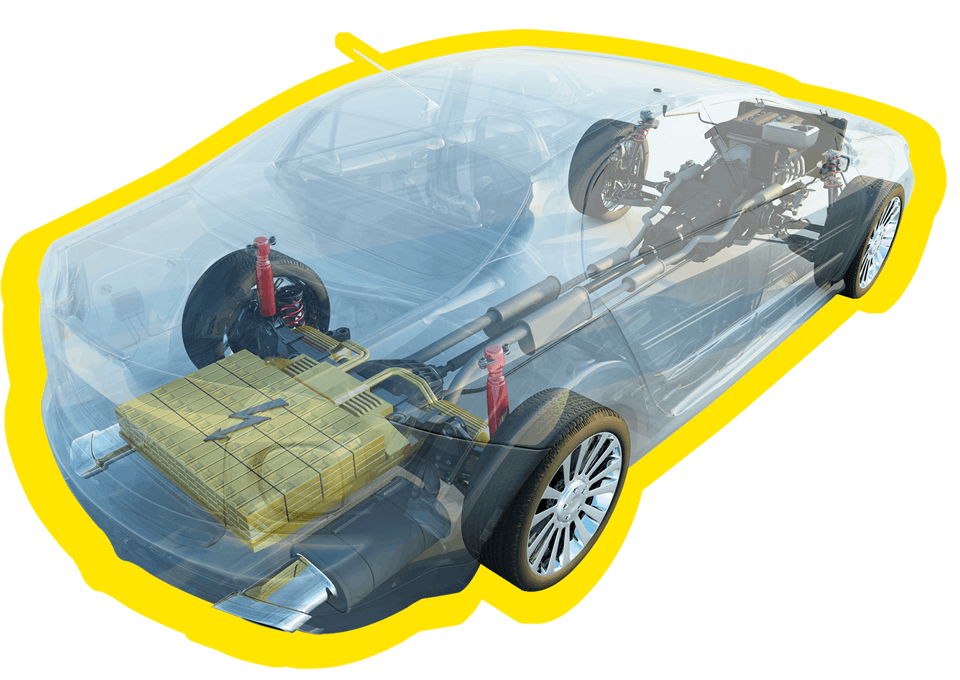

Recycling electric vehicle batteries

Our goal Become a forerunner in the recycling of lithium-ion (Li-ion) batteries for electric vehicles in France and on the European market, via a new hydrometallurgical process for recovering the desired metals.

Industrialization horizon 2026.

Alongside French and international partners, Orano is developing a safe, innovative, low-carbon process with high technological value added for recovering and purifying the valuable materials contained in battery modules (cobalt, manganese, nickel, lithium, graphite) for reuse in new components. Orano brings over 40 years of expertise in recycling nuclear materials, materials chemistry, hydrometallurgy and process industrialization.

30 millionbattery-powered electric vehicles and rechargeable hybrid vehicles in circulation in the EU by 2030

The Stable Isotope Laboratory (LIS)

Our goal Produce ultrapure stable isotopes for high-tech markets such as healthcare, quantum computing and basic research. Start of production 2023 First delivery Early 2024.

Harnessing its expertise and mastery of cutting-edge technologies in the transformation, conversion and enrichment of uranium, in under three years Orano has developed a new line of innovative products: stable isotopes. These non-radioactive isotopes of natural elements are separated in our laboratory and can then be used in a wide range of cutting-edge applications thanks to their special properties. For example, we produce silicon-28 for quantum computing, as well as xenon-129 and molybdenum-100 for the healthcare sector. This unique 3,200 m² production laboratory, located at the heart of the Orano Tricastin industrial complex, boasts an ecosystem of partners comprising SMEs, university laboratories and manufacturers.

3 200 m2 at the heart of the Orano

Tricastin industrial complex

High-performance permanent magnet recycling and manufacturing

Our goal Structure a sovereign and competitive sintered permanent magnet production industry in France to serve the European market Industrialization horizon Before 2030

Rare earths are essential components of the world’s most powerful permanent magnets, used primarily in electric vehicles and wind turbines. The market is currently strongly dominated by China, raising a sovereignty challenge for safeguarding supplies and achieving the energy transition.

Launched in April 2022 and supported by France Relance, the MAGNOLIA project brings together industrial and institutional partners operating in the high-performance permanent magnet sector: Orano, Valeo, Paprec, Daimantel France and the CEA.

The project aims to roll out used magnet recycling technologies and manufacture high-performance sintered permanent magnets for the design of more compact, light-weight and efficient electric engines.